Welcome to our community stories.

We love sharing the stories of our community members. Do you have a story you would like to contribute to our blog? Get in touch with communications@cwb.org to share your idea.

Building a Chesapeake Light Craft: We survived “boat camp”!

By Shelley Sabin

At least, that’s what it felt like at the conclusion of the 5 ½ day boatbuilding workshop that I attended in May with my best friend, Bryan.

While many woodworking novices have previously completed Chesapeake Light Craft workshops at the Center for Wooden Boats, I was fortunate enough to participate at the CWB’s boathouse at the historic Cama Beach on Camano Island. Working and sleeping in buildings from the 1930s added a level of rustic excitement to my first foray into boat building.

And while I’m happy to have completed the experience leaving with my very own Jimmy Skiff II (granted, still requiring 100+ hours of work in my garage), it was just as satisfying to spend the week socializing and sharing meals with my fellow boatbuilders, instructors, and CWB staff in our camp accommodations.

Larger pieces were assembled in advance by our instructors. Our first task was an introduction to sanding (we did SO MUCH SANDING) and cleaning up the epoxy, making nice smooth surfaces.

At the end of day 1 (left, above) she may have looked like a boat, but she wouldn’t float (at least not for long). Pieces were assembled by being ‘stitched’ together with copper wire. On day 2 (right, above) the boat was epoxied together with fillet, the breastplate and knees were installed, the floor got a layer of fiberglass, and the base of the seats were fitted.

On day 3 (below), upon flipping our boat, we discovered that we had epoxied a stir stick to the bottom of the hull. Thankfully our awesome instructors Casey Wilkinson and Dutch were able to remove it with a heat gun (no fires were started in the process).

At the end of Day 3, her skeg was added and the exterior of the hull had received fiberglass. Bryan and I signed the underside of our bow seat before sealing and installing. It’s like a time capsule that, hopefully, no one will ever see.

On day 4 she was filled with foam for added floatation (below, right) – a requirement by the Coast Guard because I plan on operating her with a motor, and by the end of day 5, her seats were installed (and weighted down with literally anything heavy we could find in the boathouse) and rub rails were added (CLC wasn’t kidding when they recommended bringing extra clamps).

On the final day, after spending so much time sealing her so that she floats, Kasey cut a hole in her hull for the daggerboard (top, left). 😨 At the conclusion of 5 ½ days, I had a boat ready to bring home to continue working on in my garage and newly learned woodworking/boatbuilding skills that will last me a lifetime.

My Mini, Pepper, and new Jimmy Skiff II, We Did A Thing (shortened to Thing), are shown in front of the Cama Beach cabins that we slept in over the course of the workshop.

Moving forward, my goal is to finish Thing before crabbing season begins at the beginning of July (I aim to work on her at least a little bit nearly every day) and spend my summer fishing, crabbing, and sailing around the Saratoga Passage and Port Susan.

Overall, I highly recommend this workshop to others (especially if, like me, you have no prior experience in boat building). The CWB will be hosting another workshop on Cama Beach next summer and regularly hosts in the Wagner Education Center on the South Lake Union campus in Seattle.

You Can’t Go Sailing Without Sails

By marty johnson

You don’t have to spend a lot of time around the Center for Wooden Boats to learn that their boats require constant maintenance. Pumping bilges, sanding and painting, and refastening hardware are everyday activities for staff and volunteers in the livery and boatshop. Wooden boats, especially wooden boats used every day by the public, take a lot of work.

The same holds true of the more than 200 sails CWB had in its inventory at last count–each tack, each shaking luff, and each ray of sunshine takes its toll on sailcloth. After just a few years in the livery fleet, a crisp new sail is turned into a dingy brown patchwork of sail tape and fraying threads. The fabric may become so weakened that tiny pinpricks grow into large rips, and the slightest tug leaves a giant tear.

For many years, a small group of volunteers have supported the sailing livery by inspecting, cataloguing, and repairing the sails. The institutional memory of the sail team stretches back more than a decade, when the team had storage and workspace in the old Naval Reserve Armory building. When that space was claimed for MOHAI staff offices, the sail team spent years working out of CWB’s North Lake Union warehouse. Many frigid evenings were spent sewing in that unheated and uninsulated building! Since 2019, the bulk of CWB’s sail work has been done in the Wagner Education Center sail loft.

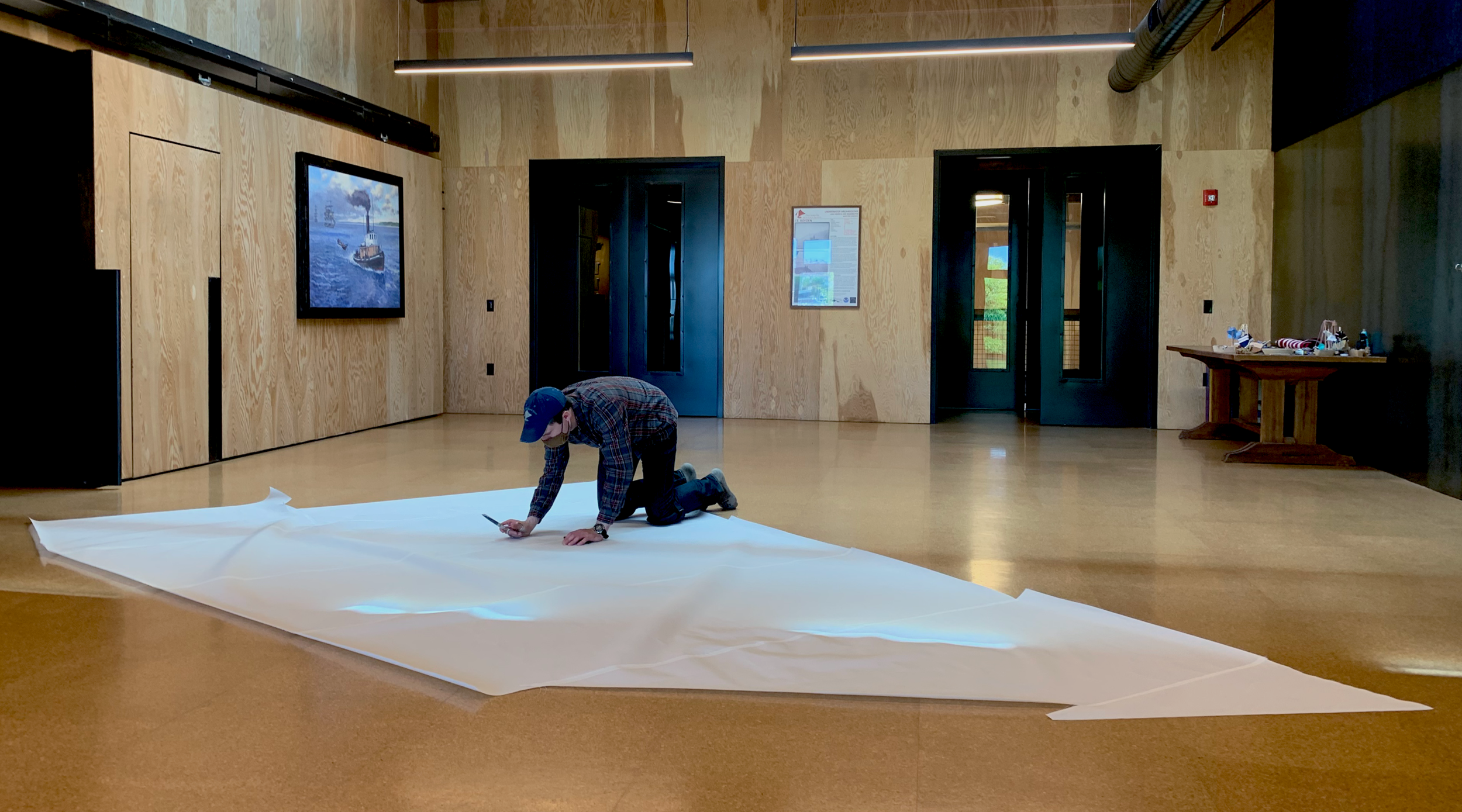

One of the exciting new opportunities for the organization provided by the Wagner Education Center is the cork flooring throughout the new building’s second story, a traditional sail loft feature. In addition to the large and comfortable workspace, we can now lay out new sails by pinning them directly into the self-healing cork floor.

Despite the intervention of a pandemic, since moving into our new space the sail loft team has already produced brand new mainsails for the livery’s Beetle Cat and Kitten (seen here to the right) and several jibs for our Blanchard Junior Knockabouts. Jibs for the remaining BJK’s, as well as a mainsail and mizzen for the new Hvalsoe 16 (built in honor of CWB Curator Shelby Allman’s late father), are currently in the works. Later this year, we plan to begin replacing the BJK mainsails that were donated in 2017 and are now approaching the end of their useful life.

Sailmaking combines the craft of sewing with the science of creating a 3-dimensional airfoil out of 2-dimensional fabric panels. Part of the fun of making sails for CWB’s diverse livery fleet is that each rig has its own unique features and requirements for the sailmaker. We start by laying out sailcloth in the rough shape of the final sail. Each panel is typically 18 to 36 inches wide, and the seams between them are curved to control the sail’s draft. The seams are basted with a special double-sided tape and then sewn on a machine that uses a zig-zag stitch. Each of the sail’s edge curves is also carefully shaped and faired using a long batten to provide the desired draft while minimizing flutter. The sails are finished with reinforcing corner patches, reef points, hemmed edges (“tabling” in the sailmaker’s lexicon), and whatever hardware is required by the rig. Once the sail is done, the next repair job or new build is already getting started.

Next time you hear the crackle of new sailcloth on one of CWB’s boats or see a fresh patch on a torn leech, remember that volunteers made it happen! And if you find yourself in the WEC while we are at work in the sail loft, don’t hesitate to stop by and take a look.

Marty is a CWB volunteer and serves on the CWB Board of Trustees.

If I’m Going to Build a Boat, I Might As Well Learn How to Sail One

By Brian stack

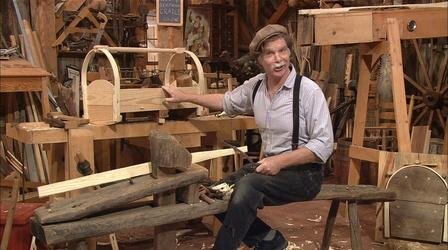

Growing up, the PBS show Woodwright's Shop was on my family's tv a lot. Roy Underhill could always get us to sit and watch him build plain pine boxes, Welsh stick chairs, and more. I helped with projects around the house like garden trellises and garage shelving but never anything like what we saw Roy accomplish with his hand tools.

When I was older and finally had space for it, one of the first things I did was go out to a big box store and buy a handsaw, a mallet, and some chisels with intent to build a small box. My first attempt did not turn out very well, although we still have it and use it for storing tchotchkes. Slowly, over time, with the application of hundreds of hours of youtube videos, the gaps in my dovetails shrank and the ambitions of my projects grew. One day, as I was looking for my next project I stumbled across Leo Goolden and his project to restore the 110-year-old wooden sailing yacht, TALLY HO. It had not crossed my mind that someone could do work like what I saw there and I was hooked immediately.

Roy Underhill at the Woodwright’s Shop on PBS.

Leo Goolden at work in TALLY HO. Follow Leo’s work here.

The challenges of building a boat were exactly what I was looking for. The fair curves, interesting angles, and ultimate need to be watertight make for an interesting task. Plus the fact that the finish isn't primarily aesthetic, needing to stand up to much harsher conditions than would be expected of a dining room table. The form and function go hand-in-hand for boats in a way that is hard to find anywhere else.

I started looking for where to learn about how to go about boatbuilding and found CWB. Unfortunately there was no way to get involved in the boat shop due to covid, but the SailNOW! program was available and I figured I may as well learn how to use a boat if I'm going to build one. Growing up, the only boats I had ever been on were the pontoon boats that look like floating front porches dotting the lakes of Western Pennsylvania. Probably unsurprising to anyone reading this post, I found that sailing was very enjoyable and much more approachable than I had expected. This was a perfect way to enjoy what Seattle had to offer and CWB is the perfect place to do it. There's an appeal to wooden boats that work as hard as the livery does. The dings and scratches tell a story about all of the people who use them.

I started volunteering at the livery at the beginning of this year and am loving being able to help families rent boats through the peapod program while also learning some basics about maintaining these lovely boats. I've found the livery volunteering at CWB almost by accident, but I'm very glad I have. The small bits of boatbuilding I've started learning so far at the livery are already helping me with my plan to build a boat. On my own time I've purchased plans for a stitch-and-glue pram that I'll start construction on soon. I had much of the woodworking experience and tools I needed to start but hadn't had a chance to work with epoxy before some maintenance we did on a boat at CWB. Being able to learn how to use it correctly with experienced mentors has saved me from a lot of mistakes I would've made on my own. That doesn't even cover things like taping off and painting that I've learned so much about. As things open up more I'm hoping to get a chance to spend time in the CWB boat shop as well so I can learn even more.

CWB is fairly new to my life, but I've enjoyed my time there immensely and look forward to sticking around for a long time. Seeing so many people around the livery who have been involved for many years, I feel that I am in good company.

Brian is from Pittsburgh and has lived in the Fremont neighborhood for 3 years. He enjoys woodworking, running, and as of recently, sailing.

The Journey to Hand-building My Chesapeake Light Craft

By Mary Sue Galvin

I have an old wooden rake hanging on my living room wall. My great grandfather did not make the rake to be art, but to be a tool–for my mother, then little, so she could help in the garden. My grandfather was a gentle person who loved gardening, he raised rabbits and chickens, carved wooden spoons, and made kitchen knives, leather boots and furniture–all by hand. Visiting was always an adventure for my sister and I. We’d go off to the basement to play the Victrola, sneak up the attic to find old clothes to dress up in, or we’d run out to the garden to see what we could discover in the old rabbit hutch and tool shed. Papa John passed away before I was old enough to really know him, but my mom kept and handed down some of his tools. They are from a time when growing your food and making things you needed was a necessity rather than a luxury. Yet the things he made were beautiful as well as practical. Satisfying to make, and a source of pride.

Inspired by the rake and the well-worn kitchen spoons he made (still in use in my kitchen), I have wanted to learn woodworking since I took a shop class in high school. I’ve been very lucky to have lived on a houseboat on Lake Union for more than 30 years, and while work took me away from the water for many years, retirement has given me the opportunity to spend more time enjoying it. Sailing lessons at The Center for Wooden Boats came first–and while down on the docks, I found myself drawn to the old boats being repaired and restored. Last summer, I enrolled in a boat building class when travel plans were postponed due to the pandemic.

The Wagner Education Center, with plenty of natural ventilation, allowed a safe setting for a small class taught by Casey Wilkinson. Using a kit from Chesapeake Light Craft, we each worked on the construction of our own boat in a week. It is fair to say that I didn’t know what I was getting into–and I didn’t realize how satisfying those hours of working with my hands, making something useful, could be. Sanding, stitching, gluing, snipping and pulling stitches, and my favorite, filleting, filled the week. More sanding, more epoxy, more filleting, then paint and layers of varnish followed. I discovered a deeper appreciation for the skills of those who build and restore wooden boats, as well as my grandfather’s craftsmanship. I rowed my boat home in early November. It is beautiful as well as practical. Satisfying to make, and a source of pride.

I’m looking forward to hours on the water this summer, and deepening my connection to CWB by volunteering. Both are great ways to enjoy this beautiful place we call Seattle.

Mary Sue Galvin is a retired nurse practitioner who enjoys water via swimming, boating, and floating on it. She has lived on her houseboat in Lake Union with her husband Dave since 1986.

Do you have a story you would like to contribute to our blog? Get in touch with communiations@cwb.org to pitch your idea.